Quality

After many years of manufacturing gears and related products for many different industries, we have developed a quality program that will normally meet or exceed our customers needs. We have passed many different quality standards and surveys used by our many customers, always passing quality audits the first time through.

Our quality program encompasses every aspect of our business. With written directives covering everything from the quote process through final inspection of the finished product. Our quality manual is available to our customers for review of all our processes, procedures, and quality forms used. We have internal inspection forms for our final inspection, or in some cases we use our customers forms. We always do first piece, in process, and final inspection from our procedures, and documents. All final inspection forms are kept on file in our quality department for any future need.

Please note that we are doing gear tooth element inspection on our MAG PH 40 Gear Analyzer, as well as our Digital Height Gauge 1D model OPTIHITE 600, and both will check up to a 24″ diameter gear, internal or external. With the CNC controls we can produce charts for every gear tooth featureWe sharp all hob & cutter in house.

We have WMW german make hob sharpening machine which result us for finish of component to its accuracy

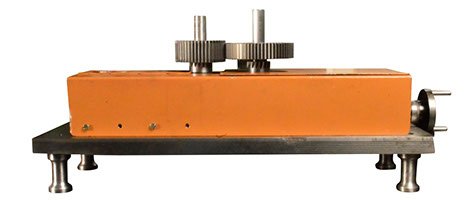

MAAG GEAR TESTER : ONE

Roll Tester For Gear Inspection.

Digital Height Gauge 1D model OPTIHITE 600.

Precision Inspection Grade Surface Plate.

SIC Make EC9 Electrical Operated Marking Machine.

WMW German make HOB Sharpning Machine.

Copyright Claim 2023/24 Developed By www.westorytellers.com